Understanding Significance of Effective Supplier Qualification – by taking example of recent FDA warning letter

Supplier qualification, especially of CMOs and API manufacturers, is a critical yet sometimes underrated aspect in the industry. In many cases, the Marketing Authorization/Product holder heavily relies on manufacturers for Production/Testing activities. Establishing a robust and risk-based Supplier Qualification process, including thorough GMP audits, is crucial to ensure quality and compliance.

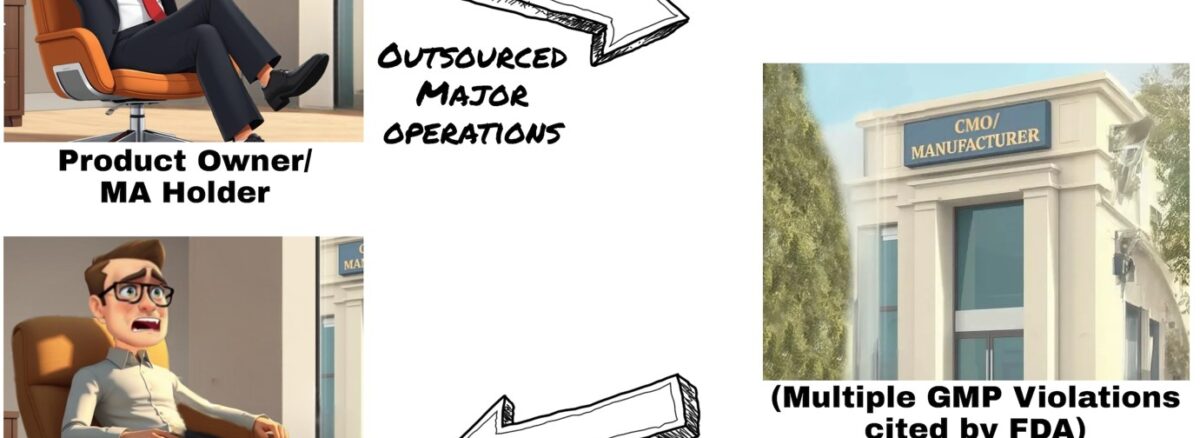

A warning letter from an FDA inspection in July 2024 serves as a crucial wake-up call for pharmaceutical companies neglecting supplier qualification. This situation emphasizes the importance of thoroughly qualifying vendors and underscores the critical role that supplier auditing plays in this process; routine evaluation/audit based on the associated risk is also equally important. In this instance, the Product owner/holder was utilising a CMO as a contract manufacturing site for their products. Based on the FDA inspection revealing multiple GMP violations at this CMO site in October 2023, it triggered the inspection at the Product owner/holder site, which was carried out by the FDA in Nov/Dec 2023 and end-up issuing the warning letter to them.

The warning letter to Product owner/holder from USFDA issued states, “your firm utilized CMOs to manufacture your ophthalmic drug products; however, your firm failed to have adequate procedures to ensure all ophthalmic drug products produced for your firm met appropriate quality attributes. You also failed to have adequate supplier qualification procedures to ensure that the drug products received from this CMO were manufactured in compliance with cGMP prior to being distributed in the United States’’. This makes it very evident to businesses with intricate supply chains about how crucial it is to always uphold compliance of your CMOs/suppliers which can only be possible with the thorough supplier assessment and audit by competent auditor at the time of selection process. It emphasises how crucial the Auditors’ role is to reduce the risks associated with business continuity.

All these started from the FDA’s inspection of CMO site being used by this product owner, where several alarming deficiencies were noted at a facility responsible for manufacturing of the drug product. These deficiencies were not merely procedural but directly impacted the quality and safety of the final products, posing a risk to patients and leading to significant regulatory repercussions causing these drug products to be adulterated. Among the issues cited were:

- Inadequate Environmental Controls

- Poor Documentation Practices

- Insufficient Supplier Oversight

- Inadequate Corrective and Preventive Action (CAPA) Processes

One of the main root causes of this debacle for Product owner is the reliance on contract manufacturer/supplier without rigorous Qualification and routine oversight. These findings highlight a common and some of them are obvious issues which could have been easily identified (and rectfied) through the EFFECTIVE Audit by the COMPETENT Auditor during supplier qualification/routine audit. While having an internal supplier auditing team is beneficial, it may not always be practical, especially for organizations with multiple/global suppliers. This is where third-party auditing groups like us play a vital role. When selecting third-party auditing partner, Expertise, Integrity, and Independence are paramount, particularly when your product’s reputation hinges on the performance of your CMO.

PHARMALANE UK has completed numerous audits of CMOs and other manufacturers/suppliers globally, uncovering significant issues in some cases. Such effective audit and outcome allowed the Product owner to make informed decisions to either “Select” (with corrective actions) or “Reject” a supplier, ensuring the protection of their product and reputation in the market.

The reputational damage resulting from these compliance issues cannot be reverted. In the pharmaceutical industry, trust is paramount, and any hint of non-compliance can lead to a loss of confidence among healthcare providers, patients, and regulators. The fallout from these issues underscores the importance of rigorous vendor qualification processes and the role EFFECTIVE auditing can play in preventing such scenarios. Pharmaceutical companies can avoid the severe consequences of regulatory non-compliance also by integrating third-party auditing into their vendor qualification process if the internal resources are not sufficient.

In conclusion, the recent FDA inspection findings serve as a powerful reminder of the importance of rigorous vendor qualification in the pharmaceutical industry. Implementing effective supplier evaluation/auditing is not just about avoiding regulatory penalties but safeguarding the health of patients, protecting the company’s reputation, and ensuring the long-term success of the business. As it is a normal trend lately that the companies continue to rely on CMOs/suppliers for key aspects of their operations, selecting the right auditing partner becomes more important. We wouldn’t boast, but PHARMALANE UK has been truly evolved as a highly trusted partner for the GMP Auditing of the CMOs/ suppliers across the globe and in addition to our total of over 600 EXISTING CLIENTS globally, over 200 NEW CLIENTS are trusting us every year for their supplier auditing requirements.

Penned by:

Dr. P. B. Tank,

Chief Quality Officer

PHARMALANE UK Ltd.